There may be cases when you want to move an object a longer distance than what the actuator's stroke length is. You can achieve this by using a telescoping actuator or you can use the physics of mechanical leveraging to your advantage. Common examples of this are the scissor lift or what our friend Mike Senna, the creator of the Wall-E Robot, did with his DIY Chicken Coop Automatic Door Opener.

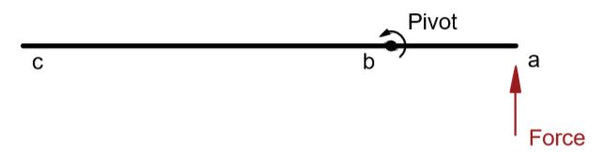

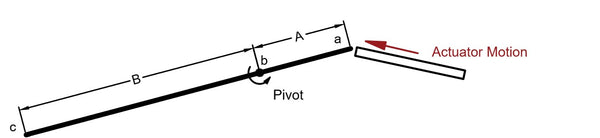

The physics behind these applications is using a ratio of distances from the pivot point on each side. As you can see in Figure 1, the actuator is mounted at point a with a fixed pivot at point b. By taking the ratio of B and A, you achieve a ratio of . This means that point c will rotate R times more than the stroke of the actuator. However, this will increase the amount of force required by the actuator and rotational speed of point c by R times.

Figure 1: Member Rotating Around a Pivot Point

DIY Chicken Coop Automatic Door Opener

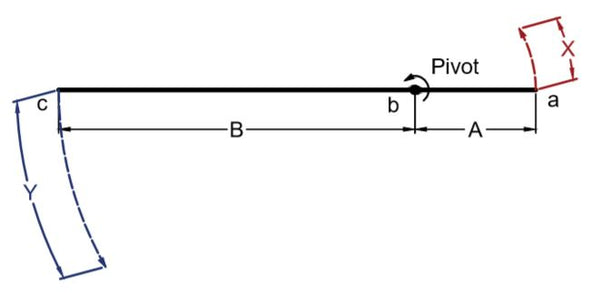

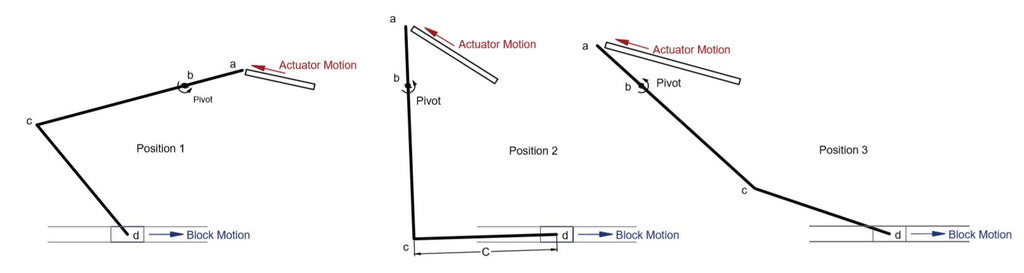

Mike Senna's application uses the same principle discussed above and also provides a great example of adding another member to convert the rotation of point c back to a linear motion. You can see in figure 2 that the top member rotates around the pivot point and the actuator pushing at point a.

Figure 2: Top Member Rotating Around a Pivot at Point b

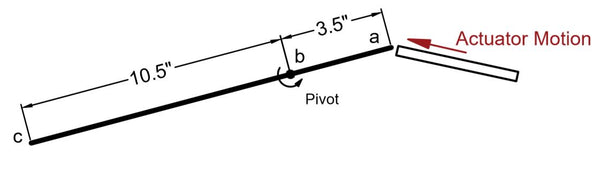

Mike knew that he needed the Chicken Coop door to open approximately 18 inches. “The first thing to consider is the ratio of the movements,” In order to make the ratio R equal to three to ensure that point c would travel 18” with a 6” stroke, he placed the pivot point ¾ towards point a (figure 3). Mike did this by positioning the arm so that “3.5 [inches was] on one side of the pivot point and 10.5 [inches] (3.5" x 3) on the other side.”

Figure 3: Top Member Rotating Around a Pivot at Point b with Dimension

After this, Mike added another member to transform the rotational motion to linear. He explains, “My solution was to add another arm whose purpose is to adjust for the arc as one end moves in an arc and the other end adjusts to a linear movement.” Figure 4 is a diagram made for his DIY Chicken Coop Automatic Door Opener project shown at various different positions along its travel. Note that the speed of the chicken coop door and force applied by the actuator will change throughout the travel. It was now a matter of adjusting the positioning to achieve the door travel he desired.

Figure 4: Chicken Coop Door at Three Different Positions

The Scissor Lift

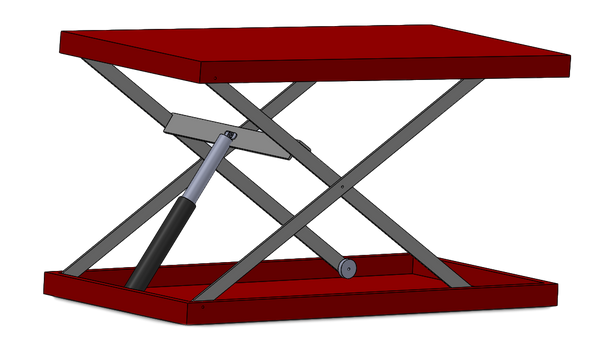

The scissor lift is another application that uses this principle to achieve more linear motion with mechanical leveraging. To provide an example, a 3D model was created to simulate an actuator with a relatively short actuator lifting higher than the stroke of the actuator.

Figure 5: 3D Model of a Single-Stage Scissor Lift

As you can see in Figure 5, an actuator with a relatively short stroke (8 inches in this case) was used to lift 36 inches. Scissor lifts work with the same principle where a body rotates around a pivot point and a mechanical advantage is created. However, instead of adding another member whose purpose is to simply translate the rotational motion of one end to translational, the motion of the ends of members are restricted to a horizontal direction. This results in the direction of the force being only upwards.

What is interesting about the scissor lift is that if the actuator is mounted on the upper half, the lift will raise as the actuator extends. However, have the actuator mounted on the lower half and the lift will raise as the actuator retracts. Also note that the closer the actuator is mounted to the mid-joint of the members, the more the lift will raise, but will require more force.